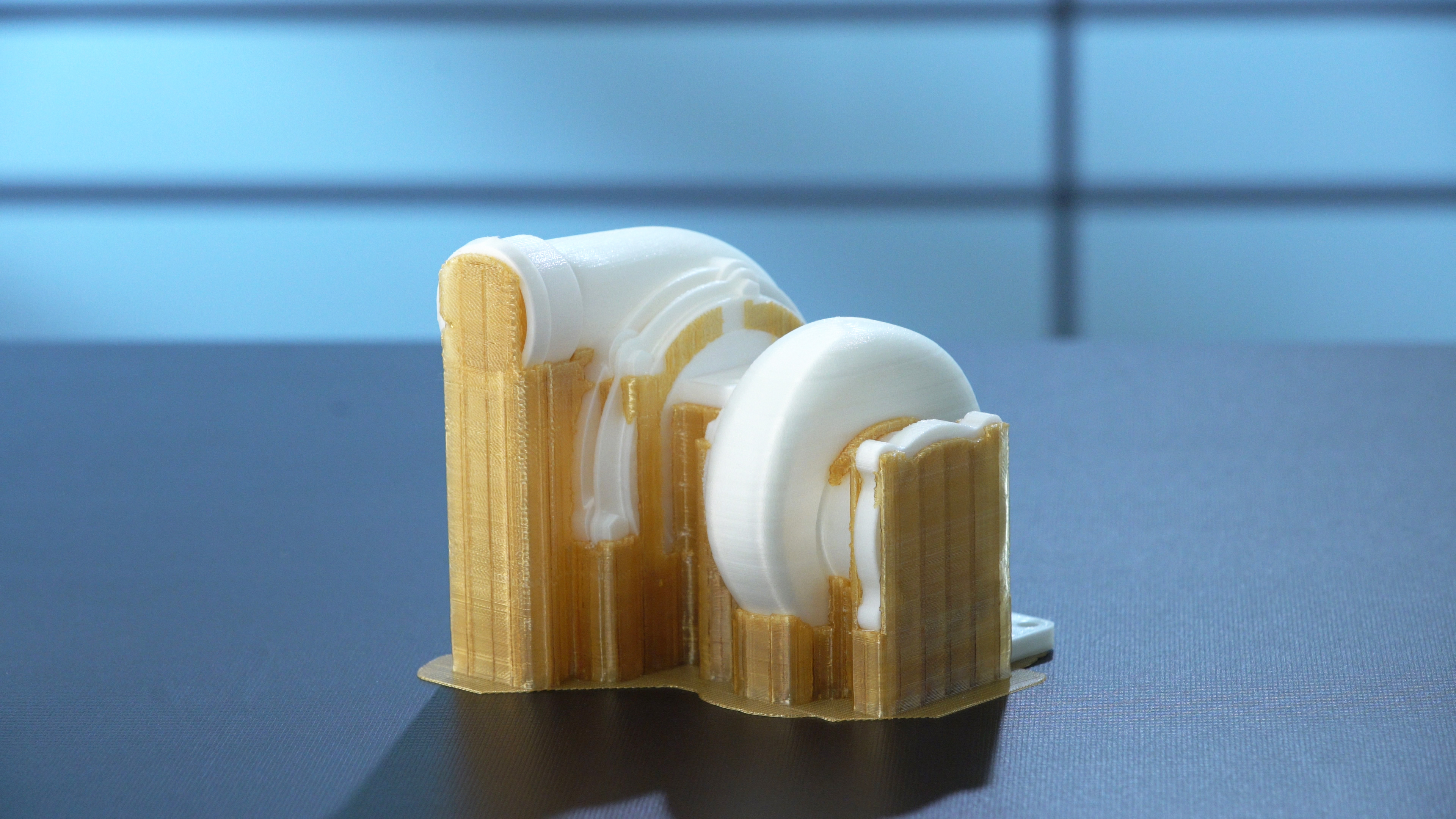

Annealing will maximize mechanical, thermal and chemical resistance properties. Print speed: 10-50mm / s for 0.2mm layer height, fast as indicated by results Annealed (post crystallization)ģD printed PEEK parts: PEEK printed parts must be annealed after printing to increase the crystallinity of the resin. The material has excellent interlayer adhesion, resulting in greatly improved impact resistance, strength, durability, and the printing process.Įxtruder temperature: 375 - 410 ° C (lower than competitive PEEK filaments)Ĭase temperature (if your printer is equipped): 70 - 150 ° C These properties make PEEK filament especially suitable for use in FDM and FFF 3D printers. PEEK filament has unique properties because it does not come into contact with water during the production process and is packed directly in vacuum packaging. PEEK is used to manufacture articles used in demanding applications in the aerospace, automotive, oil and gas, and medical industries. PEEK is considered one of the highest performance engineering thermoplastics in the world.

PEEK is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance properties that are preserved at high temperatures. Last edit at 10:34AM by relytyarg.PEEK polymers of polyether ether ketone (PEEK) are obtained by gradual growth polymerization. (☌): 130 | |Water Absorption (%): 0.01 | Oxygen Index (%): 60 | Flammability UL94: V0 | Volume Resistivity (log ohm.cm): 15 | Dielectric Strength (MV/m): 40ĭissipation Factor 1kHz: 0.002 | Dielectric Constant 1kHz: 2.6 | HDT 0.45 MPa (☌): 115 | HDT 1.80 MPa (☌): 76 | Melting Temp. [ Density (g/cm3): 1.7 | Surface Hardness: RR93 | Tensile Strength (MPa): 30 | Flexural Modulus (GPa): 1.7 | Notched Izod (kJ/m):1.06+ | Linear Expansion (/☌ x 10-5): 20 | Elongation at Break (%): 200 Not sure if there is a history of using ECFTE in 3d printing though.

If you can find a supplier ECTFE is similar in price to the other flouropolymers, with a lower melt temperature and mechanical and chemical properties approaching that of FEP or PTFE. My company is called e3d-online - you can buy at [ Hey, I work for a plastics extruding company that deals with PTFE a great deal, and depending on what exactly you are making, you may want to consider using ECTFE if possible. I am deadly serious when I say I want to print a working J-Head type hotend out in full, using dual extrusion of FEP and PEEK, but obviously with a brass nozzle. Then printing on the raft continues as normal. To get FEP to stick I would probably go for a mechanical route, using an over-extruded raft on something like perfboard, so plastic flows through the holes, die swell causes it to mushroom slightly on the the other side of the hole locking the raft to the bed. You can see more details on the extruder in the link in my signature. I would be using my E3D-v4 All metal extruder, which has 316 Stainless and brass in contact with the molten plastic. Resin pellets are much more available than filament.Īs far as I know neither are particularly harmful to the processing equipment. I am going to invest in a filastruder or similar at some point once they are a little more prove - or make my own. My stumbling block in both respects is acquiring filament. I have considered printing both PEEK and FEP (Which is a fluoropolymer like PTFE, but can be conventionally melt processed as a thermoplastic) Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki,, is for everyone and everything! Let us know how it's going in reprap-dev, eh? Since you're a dev. You may also have trouble with your splines not gripping the teflon, but some (if not all?) of our stuff works with hdpe, which is quite slippery, so ? I'd also worry about the plastic parts of your extruder melting since you may be running your hot end higher than normal. You'll probably want to pipe the fumes out a window.Īlso, you'll probably want to try a hot end with no ptfe/peek parts, like: Sounds like it's going to be off-gassing quite nastily before it gets soft enough to extrude. These degradation byproducts can be lethal to birds, and can cause flu-like symptoms in humans. While PTFE is stable and nontoxic, it begins to deteriorate after the temperature of cookware reaches about 260 ☌ (500 ☏), and decomposes above 350 ☌ (662 ☏). Animal studies indicate that it is unlikely that these products would be generated in amounts significant to health at temperatures below 250 ☌ (482 ☏), although birds are proven to be much more sensitive to these decomposition products. The pyrolysis of PTFE is detectable at 200 ☌ (392 ☏), and it evolves several fluorocarbon gases and a sublimate. According to DuPont, its melting point is 327 ☌ (621 ☏), but its properties degrade above 260 ☌ (500 ☏)

0 kommentar(er)

0 kommentar(er)